Phase III of Jiaozi Park Financial City

-

Location

Chengdu, Sichuan

-

Client

Chengdu Jiaozi Park Yuerui Enterprise Management Co., Ltd

-

Design

DBW

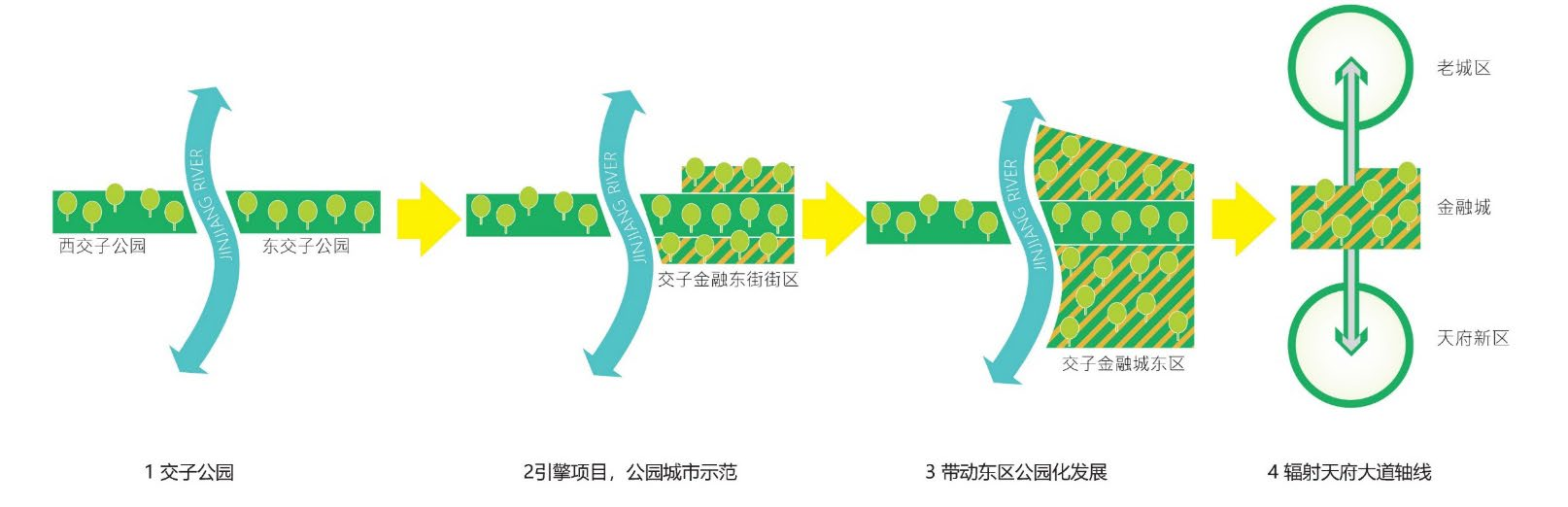

A thousand years ago, the world's earliest paper currency, "Jiaozi," was born in Chengdu, igniting the spark of the urban economy. A thousand years later, on the same land, the Jiaozi Park Financial Business District has emerged as Chengdu's new financial core. Among them, the Hedong District Headquarters Industrial Park (Phase III) project (referred to as "Financial City Phase III") serves as a benchmark for integrated development of "office + business district." With a blueprint of a park city, it is continuing Chengdu's financial legend

The project deeply integrates the concept of park city, and is designed and built in strict accordance with the three-star green building standard and LEED platinum pre-certification requirements. With a total curtain wall area of approximately 185,000 square meters, it integrates six office towers and a commercial podium, serving not only as an important carrier for empowering Chengdu's financial industry to build a strong circle and chain, but also as a park city model for implementing the "dual carbon" strategy and creating new urban landmarks.

Location advantage:

Cross green core, financial pulse

▲ Project location map (Plot No. 3)

The third phase of the Financial City is located in the key area of Chengdu's "three key areas for optimization and strengthening", and is the only area focusing on high-end resource operations. The project is adjacent to Jinhua Road in the east and Jinjiang River in the west, facing the Financial City Twin Towers across the river, forming the city's "financial crosshair".

Surrounded by supporting facilities such as the East TOD of the Financial City and the regional energy station, and connected to the airport and core business district through an efficient transportation network, it truly achieves the integration of "ecology, life, and production".

Design Concept:

Gold and jade intertwine, a bustling prosperity for ten miles

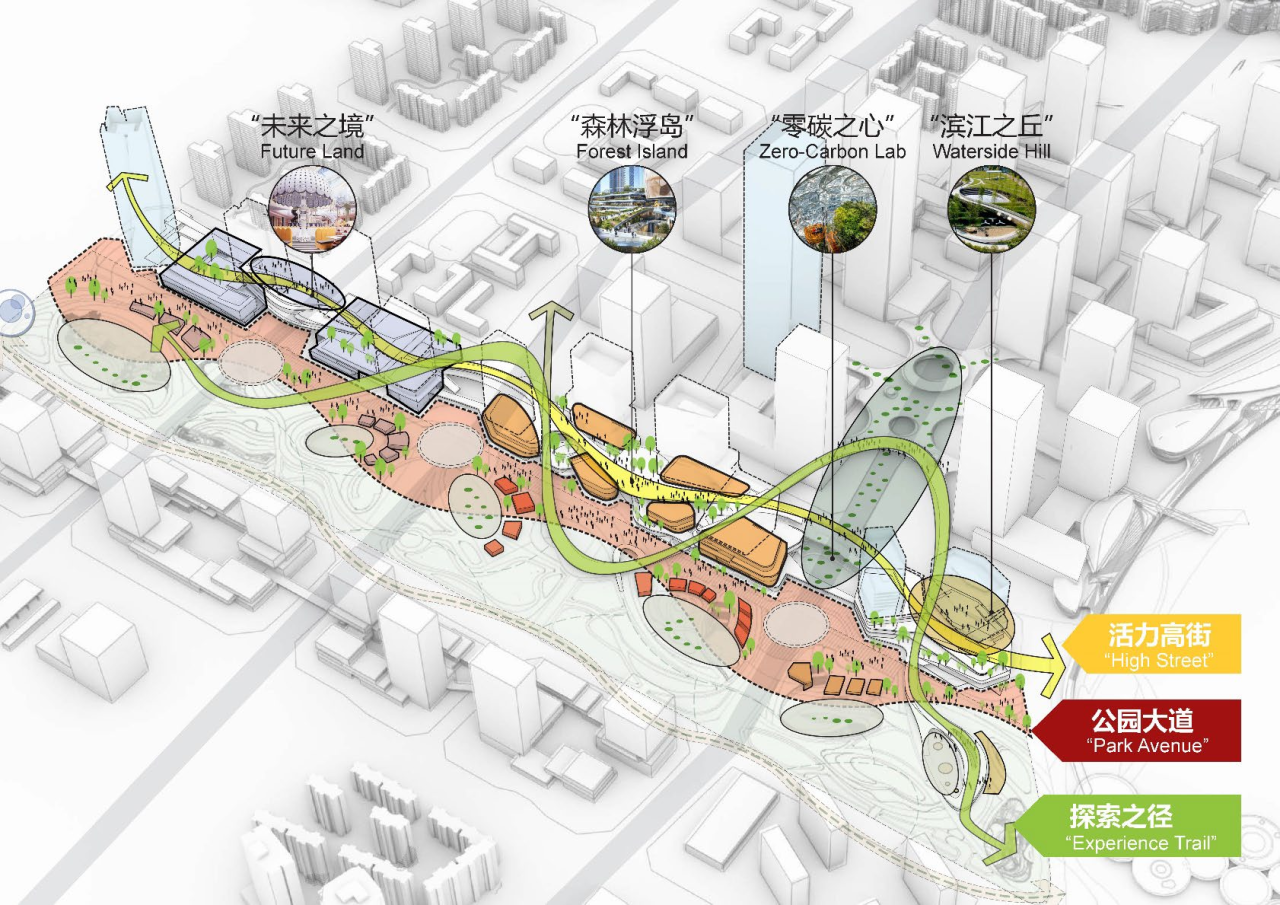

The project, with the overarching vision of "A City of Gold and Jade, Ten Miles of Prosperity, and a Happy Chengdu," aims to create a model park city that integrates urban vitality with natural tranquility.

This concept has profoundly influenced the entire process, from planning to details. Among them, the curtain wall system has become a key carrier for realizing the imagery of "golden green": the tower facade adopts a vertical hidden and horizontal transparent glass curtain wall system, echoing the greenness of the park with transparent "green" glass, and is paired with horizontal metal decorative lines to outline the "golden" business quality. Through the three-dimensional interweaving of the "golden commercial circulation" and the "green natural experience path", the project successfully constructs a park-like 24-hour characteristic street area.

© DBW

In the practice of the Financial City Phase III project, the FORCITIS team, starting from the practical pain points of long-term use of curtain walls, developed and applied multiple utility model patent technologies through refined design and technological innovation, providing reliable solutions to enhance the overall performance and long-term aesthetics of the building.

A prefabricated anti-sagging metal plate decorative strip curtain wall system

Common pain points in the industry:

In traditional curtain walls, horizontal decorative lines are the "beauty killers" of facades.

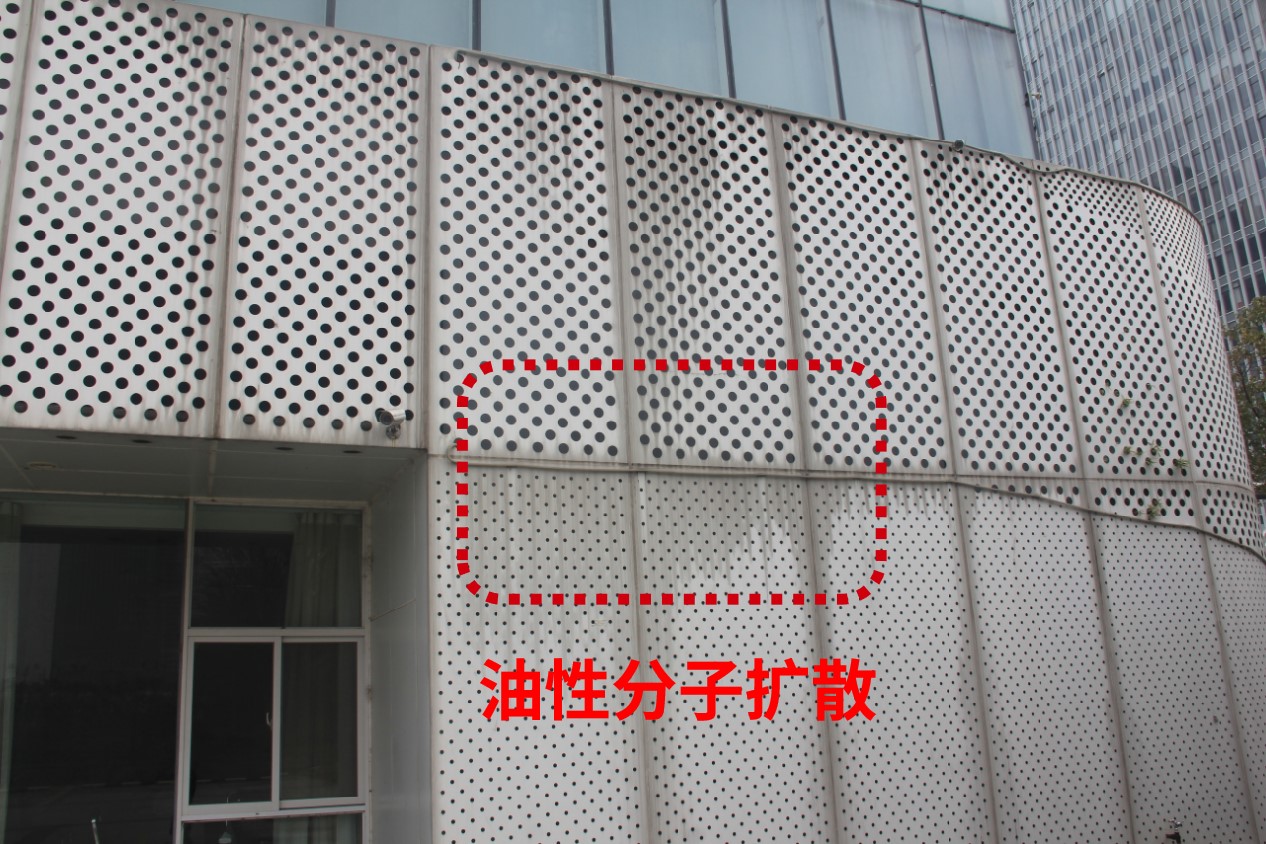

Line smudging - "external tear marks": Rainwater carries dust on the glass surface, accumulating on the slanted surfaces of the lines, forming streaks of "tear marks" that are difficult to clean, resembling dirty tear marks on a pristine facade.

Diffusion of oily molecules in sealant - "Inherent Penetration": As the sealant joint ages, the oily molecules in inferior sealant will diffuse outward, causing permanent and uncleanable contamination on facade stone materials, aluminum panels, and other profiles.

These two types of stains, when viewed from different perspectives, have distinct impacts on the architectural image and user experience. Visible from the outside are only "tear marks" stains, while the real concern lies in the indoor experience: glue residue forms a permanent, difficult-to-remove hazy film on the glass, causing the view outside the window to be permanently blurred.

© DBW

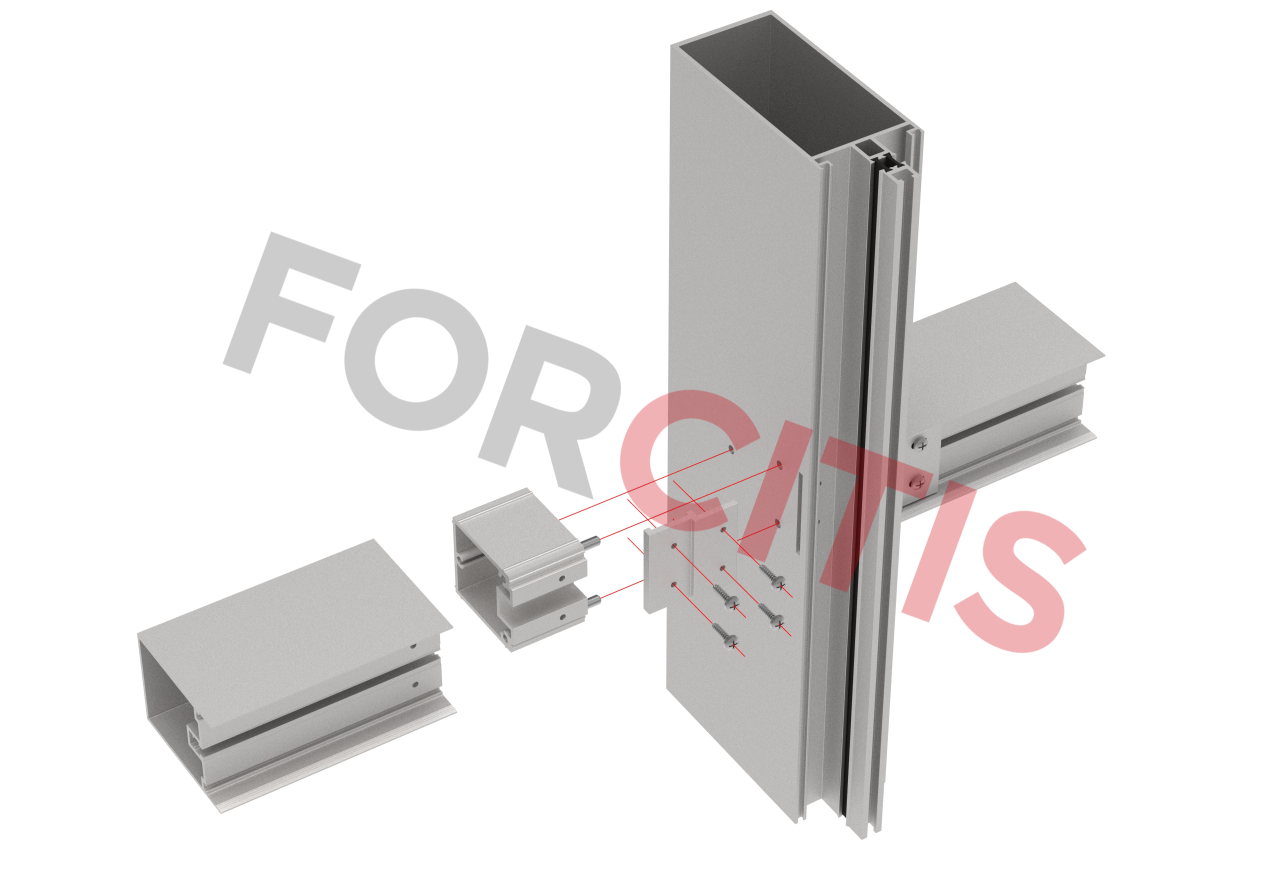

Solution and patent implementation:

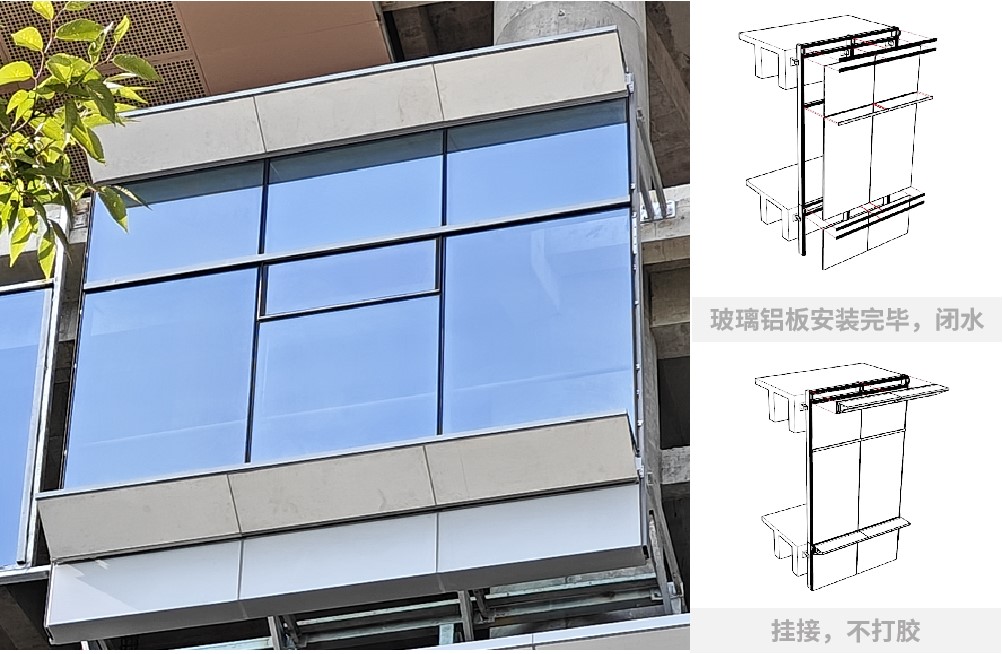

To address the aforementioned issues, the core approach of the team is to alter the flow paths of water and contaminants, and to achieve industrial production and dry installation of decorative moldings. This will structurally eliminate pollution sources and enhance installation quality and efficiency.

The horizontal decorative lines in this project are assembled in the factory as a whole frame and installed on-site in a prefabricated manner, achieving complete detachment from the main body of the curtain wall. This allows rainwater on the glass surface to flow directly downwards along the gap between the two, while sewage on the top of the lines flows downwards through a specially designed aluminum alloy drip at the front end, preventing sewage from flowing down the lines. This measure effectively reduces on-site procedures and enhances installation accuracy and efficiency.

The system eliminates the use of sealant, thereby eliminating the risks of dirt accumulation in glue joints and oil leakage from inferior sealant, significantly enhancing the long-term aesthetics and maintenance convenience of the facade.

Anti-slip beam-column bidirectional sliding connection joint

© DBW

Pain point discovery:

For the curved corners of high-rise towers, the curtain wall joists will undergo deflection deformation under wind load. The pins in traditional connection nodes have a risk of slipping out during bidirectional sliding, which may affect the local stability and structural safety of the curtain wall system.

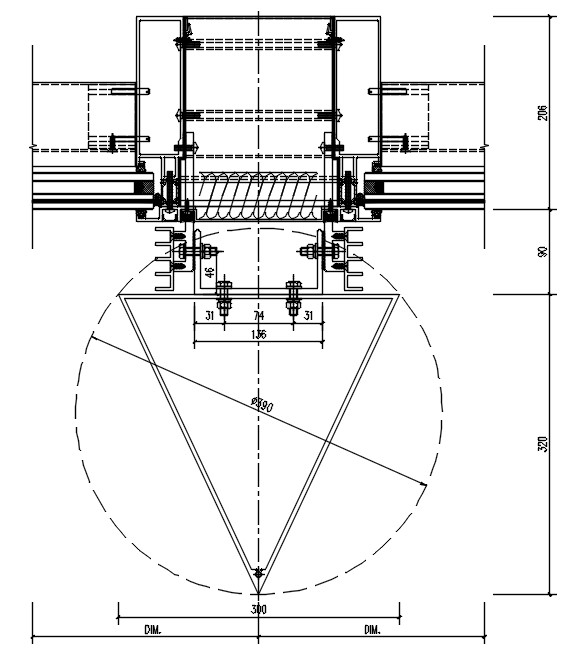

▲ Diagram of aluminum alloy profile hanging connection nodes

Solution and patent implementation:

The anti-slip connectors developed by the FORCITIS team can effectively limit the displacement of components in bidirectional sliding, significantly enhancing the overall stability of the joist system and avoiding the risk of local detachment.

The application of this technology has simultaneously optimized the design of the keel partitions, achieving better cost control while ensuring structural safety.

An open-type buckle-fastened stainless steel panel curtain wall system

Pain point discovery:

If the stainless steel columns at the lobby entrance are fixed using traditional methods, the final flatness of the panels may be compromised due to uneven stress distribution or substrate deformation, making it difficult to meet the extremely high requirements for detail quality in high-end commercial spaces.

▲ Diagram of aluminum alloy profile hanging connection nodes

Solution and patent implementation:

The stainless steel pillars at the lobby entrance feature an open buckle design, allowing stress to be released between panels and adapting to minor changes in the substrate through hanging, thus ensuring the ultimate flatness of the facade.

This system simplifies the construction process, reduces installation difficulty, and effectively ensures the detailed texture and visual quality required for high-end commercial spaces.

In the design of curtain wall systems, the FORCITIS team consistently adheres to the core philosophy of "empowering aesthetics with technology and driving efficiency through innovation". Through comprehensive innovation in materials, construction, and craftsmanship, the FORCITIS team achieves excellent architectural aesthetics while precisely balancing multiple objectives such as safety, functionality, comfort, and economy.

Material selection: Transparent, safe, and serene

The project encompasses three towers, G08, G09, and G10. Tower G08, themed "Flowing Water with Rhythm," utilizes a vertically visible and horizontally hidden glass curtain wall system, creating a building facade that stands at 83.75 meters tall and emphasizes the smoothness of vertical lines.

© DBW朗宜

The G09 and G10 towers echo the design concept of "Emerald Peaks", combining setback greening and viewing platforms to create a 112-meter-high, layered ecological architectural form.

© DBW

Structural innovation: The optimal balance between quality and cost

In terms of structural design, the team has achieved effective cost control while ensuring excellent quality through systematic innovation.

© DBW

The glass used in the tower building features an outer layer of ultra-clear laminated glass and an inner layer of ultra-clear tempered insulating glass. This design not only achieves a transparent visual effect but also systematically enhances four key performance indicators:

Better light transmission, comfortable lighting:

Fully ultra-clear glass increases the visible light transmittance by approximately 5%. Without altering the shading coefficient, it brings in more beneficial natural light into the interior, effectively enhancing the brightness of the office space.

Sound insulation and enhanced quietness:

The glass adopts a laminated insulating glass combination, endowing the curtain wall with an excellent sound insulation level of approximately 40dB. Compared to the sound insulation level of about 34dB of conventional insulating glass, the sound insulation performance is significantly improved by about 6dB, providing a more tranquil guarantee for the indoor office environment.

Safe and controllable, economical operation and maintenance:

The self-shattering rate of ordinary tempered glass is about 3‰, homogeneous tempered glass is 1‰, ultra-clear tempered glass is 1/10,000, and laminated glass is almost 0%. This project adopts ultra-clear laminated semi-tempered glass with an outer layer, which has a self-shattering rate of 0%. This significantly reduces the risk of falling from heights; the inner layer glass adopts ultra-clear tempered glass, reducing the self-shattering rate to 1/10,000. This effectively reduces the cost of replacement and maintenance caused by self-shattering in the later stage.

Excellent flatness and stable facade:

The stress of the laminated semi-tempered glass on the outer pane is only half of that of tempered glass, significantly reducing the bowing and waving changes in the glass. At the same time, the actual thickness of the outer pane (10.07mm) is greater than that of the inner pane (10mm), resulting in less deformation under temperature pressure differences, collectively ensuring the ultimate flatness and visual stability of the facade.

▲ Diagram of aluminum alloy profile hanging connection nodes

The facade design and structural system also embody the concept of refined design. The exterior decorative lines are made of hanging aluminum alloy profiles, with the diameter of the external tangent circle strictly controlled within 400mm, achieving a precise balance between facade effect, shading function, and construction cost.

For the design featuring stacked stone-like aluminum panels, the team optimized the originally designed hyperbolic twisted panels, which were challenging and costly to process, into flat polygonal panels. This significant change not only preserved the three-dimensional visual effect but also significantly reduced the processing and construction costs.

In terms of detailed craftsmanship, the tower incorporates built-in ventilators instead of traditional operable fans, ensuring natural ventilation comfort while maintaining the integrity and transparency of the facade.

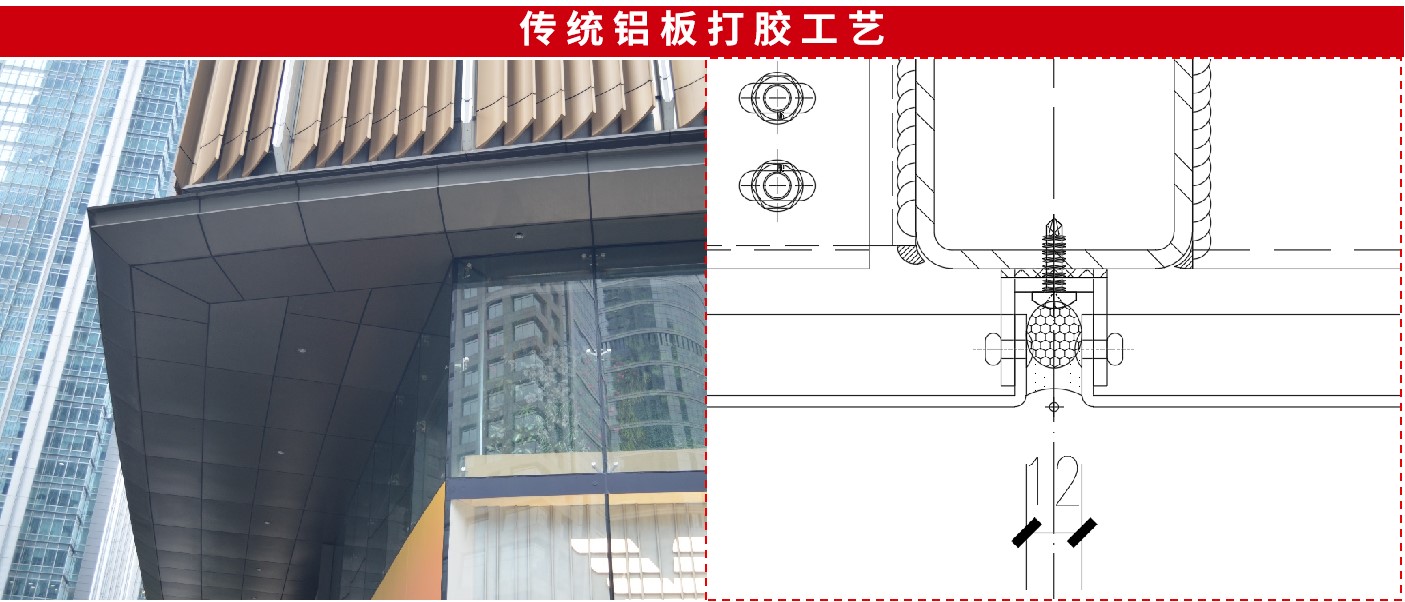

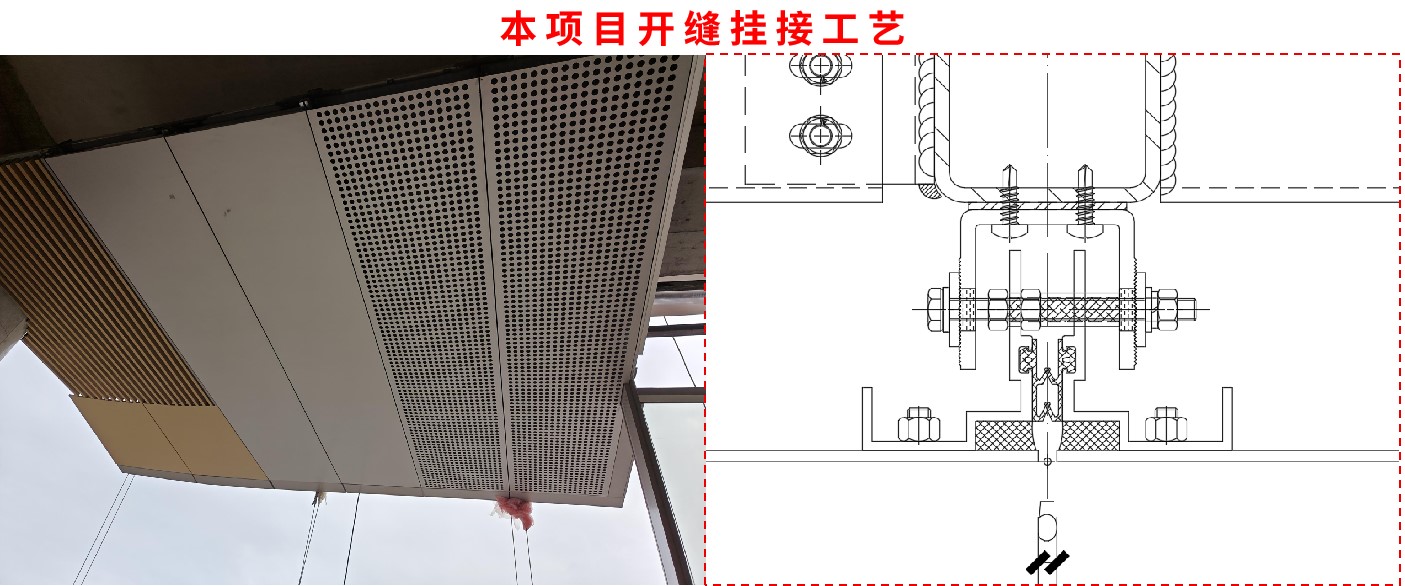

The suspended ceiling aluminum panel system abandons the traditional gluing process and adopts a slotted insertion system. The aluminum panels are tensioned and fixed by aluminum alloy frames, achieving adjustable and controllable joints. This not only ensures the ultimate flatness of the suspended ceiling but also improves construction precision and installation efficiency.

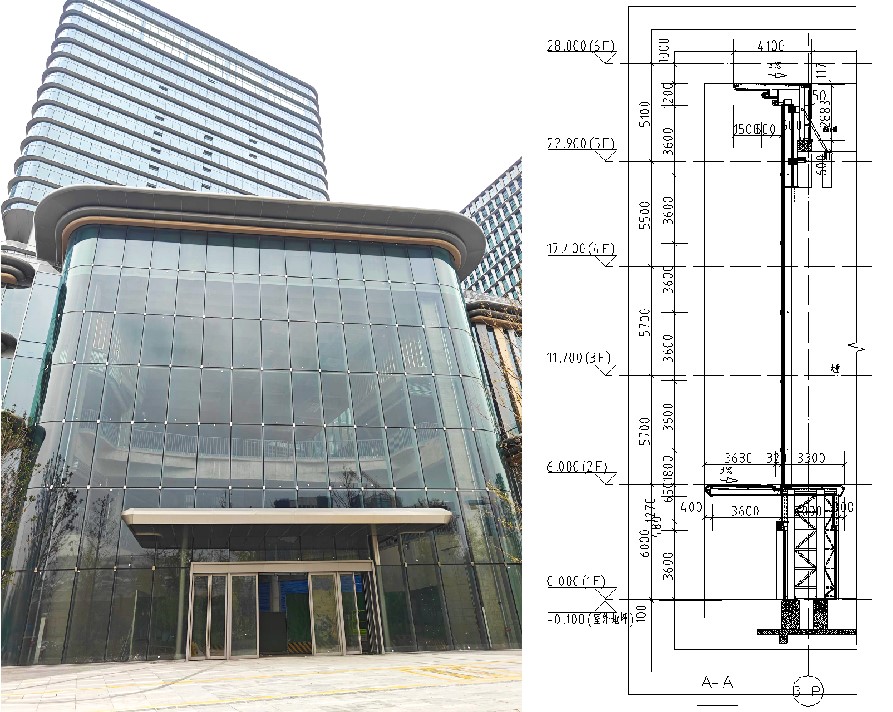

Ultra-large span precision steel point-supported glass curtain wall

The base of the tower features a super-span precision steel point-supported glass curtain wall, which opens up to the street from the park boundary, providing a widely shared space. Lush vegetation extends into the interior of the project and even permeates the streets and alleys, achieving maximum "integration with greenery" and "integration of scenery".

Facing the complex conditions of a 25.9m ultra-large span, a single cable prestress of approximately 500kN, and the inability of the main structure to bear the load of the curtain wall, the team developed a safe and reliable solution through innovative structural deduction.

The core of the plan lies in achieving structural system separation: completely detaching the canopy system from the cable curtain wall, forming an independent steel frame at the entrance of the door pocket, and fundamentally ensuring structural safety.

To achieve a lightweight appearance for the columns, an innovative double-span beam structural model is employed in conjunction with a point-supported curtain wall system. By precisely controlling the deflection, the column cross-section is reduced, balancing structural safety and cost control.

In addition, careful consideration has been given to the details of the project: horizontal round tubes are installed every two grids to ensure the stability of the large-span columns.

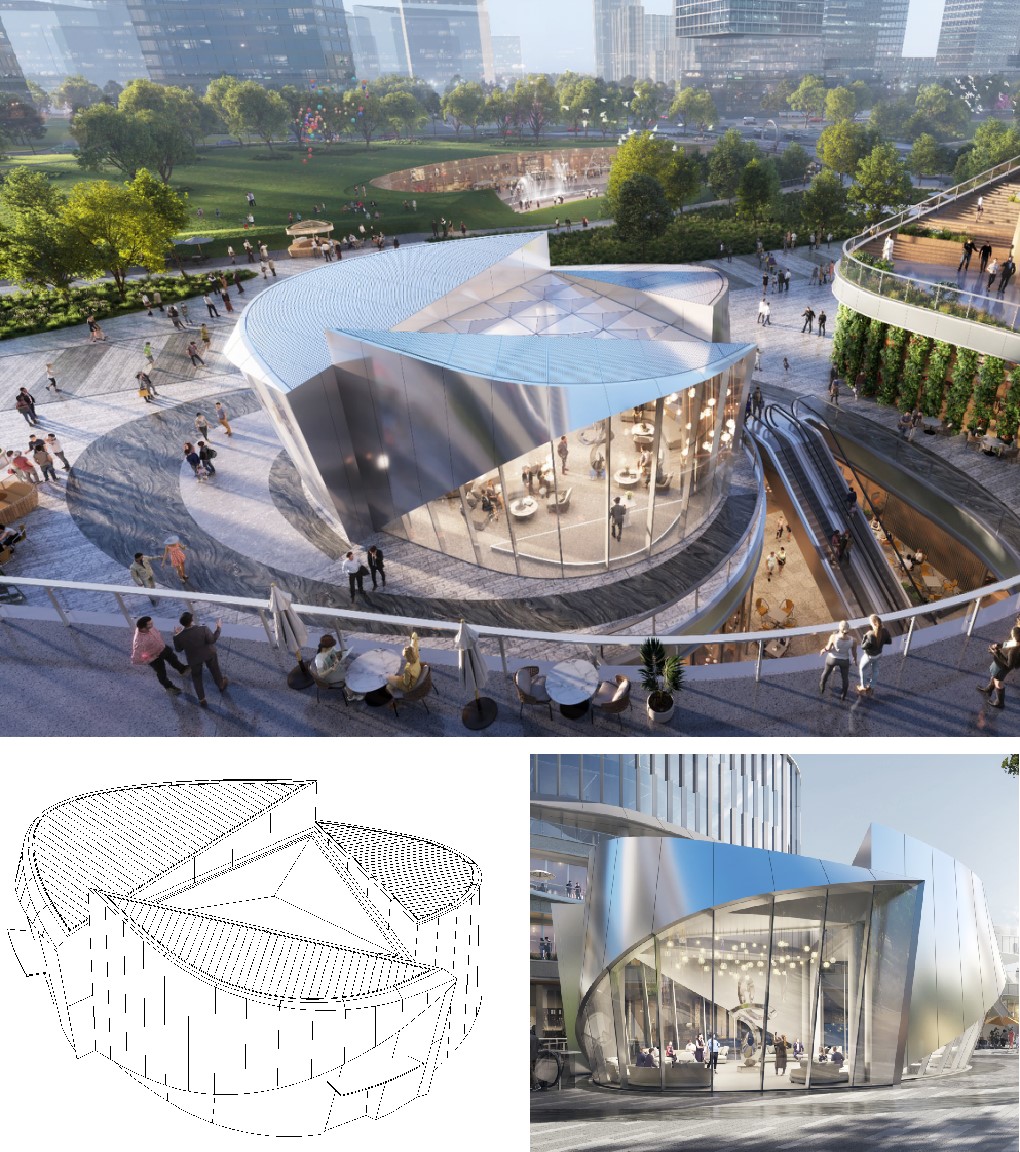

The pursuit of excellence in the double-curved facade of the specialty flagship store "Lotus"

© DBW

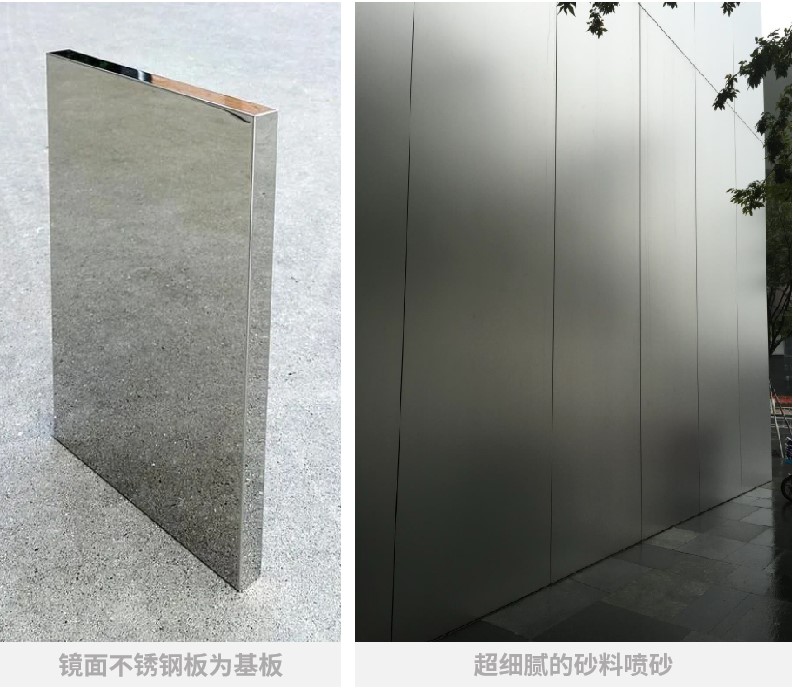

The main store "Lotus" boasts a unique design, featuring a complex hyperbolic structure. To achieve an extremely transparent visual effect, the facade is constructed using hyperbolic ultra-clear glass and 20mm thick honeycomb apple sand stainless steel plates, posing extremely high demands on materials and construction.

Challenge 1:

The original design featured a hyperbolic glass panel with a maximum height of 6.8 meters, and there are very few domestic suppliers capable of processing such a large size, leading to high costs and limited bidding opportunities. The stainless steel plates, even in oversized dimensions (up to 1.2m×8m), must maintain a flat surface, further increasing the difficulty of implementation.

Solution:

Optimizing the glass height to 6 meters, while maintaining the overall visual effect, breaks supply constraints and achieves controllable costs and fair bidding.

Challenge 2:

The glass in the partial area on the left side of the door, configured according to conventional standards (12mm+12mm), lacks structural strength. If it is uniformly thickened to 15mm+15mm, it will lead to a significant increase in cost and unevenness both inside and outside the facade.

Solution:

The innovative "slot-in" fixing solution is adopted to specifically enhance the load-bearing capacity, eliminating the need for overall glass thickening while meeting structural safety requirements and precisely controlling costs.

From drawings to landmarks, Foster has been deeply involved throughout the entire process, injecting technical strength and innovative thinking into every detail, from the macro system to the micro nodes. The project fully complies with the national three-star green building standard and is pre-certified for LEED platinum level. The high-performance curtain wall system is integrated with green technologies such as photovoltaic power generation and district energy stations, laying a solid foundation for low-carbon operation throughout the building's entire lifecycle.

Nowadays, with the architectural image of "Emerald Peaks" fully presented at the cross-shaped green core of Jiaozi Park, this project has transcended being merely a headquarters office space and become a sustainable model that responds to the multiple expectations of the city, users, and the environment. It marks the continuous evolution of Chengdu's financial genes towards a greener, more humane, and more intelligent future in the context of the new era.

-

Sanya Merchants Kechuang PlazaCreate a minimalist and pure visual effect of office facade.

Sanya Merchants Kechuang PlazaCreate a minimalist and pure visual effect of office facade. -

Dongguan Zhengzhong Science ParkThe facade design is combined with thousands of miles of mountains and rivers and high mountains and rivers to create a brand-new image cover of Greater Bay Area.

Dongguan Zhengzhong Science ParkThe facade design is combined with thousands of miles of mountains and rivers and high mountains and rivers to create a brand-new image cover of Greater Bay Area. -

Shenzhen Shenshan Science and Technology Ecological ParkWith the help of elegant and changing facade design, a new generation of industrial parks will be built.

Shenzhen Shenshan Science and Technology Ecological ParkWith the help of elegant and changing facade design, a new generation of industrial parks will be built.