AMEC Nanchang R&D base project

-

Location

Nanchang

-

Client

Nanchang City Micro Real Estate Co., Ltd.

-

Design

The IT Electronics Eleventh Design&Research Institute Scientific and Technological Engineering Corporation Limited

-

Building Area

About 140000㎡

AMEC Nanchang R&D base project

▲ overall perspective

On July 7,2023, the company held a ceremony to inaugurate the new factory in Nanchang, announcing that its wholly-owned subsidiary AMEC Nanchang R&D base project was officially completed and put into use. The completion of AMEC Nanchang R&D base project, which covers an area of about 130 mu and has a total construction area of about 140,000 square meters, further enhances the company's product development and production capacity. It is an important milestone in the development of AMEC and a new starting point for future innovation.

The base is equipped with industry-leading laboratories, high-standard clean rooms with cleanliness of grade 10, advanced production workshops and efficient logistics and warehousing centers. It also provides employees with a comfortable office environment and leisure living area.

The production R&D building is the main entrance of the whole base. The building structure is a reinforced concrete frame structure. The facade includes aluminum curtain wall, glass curtain wall, aluminum awning, stone cladding column, glass sun room and other categories.

▲ realistic picture

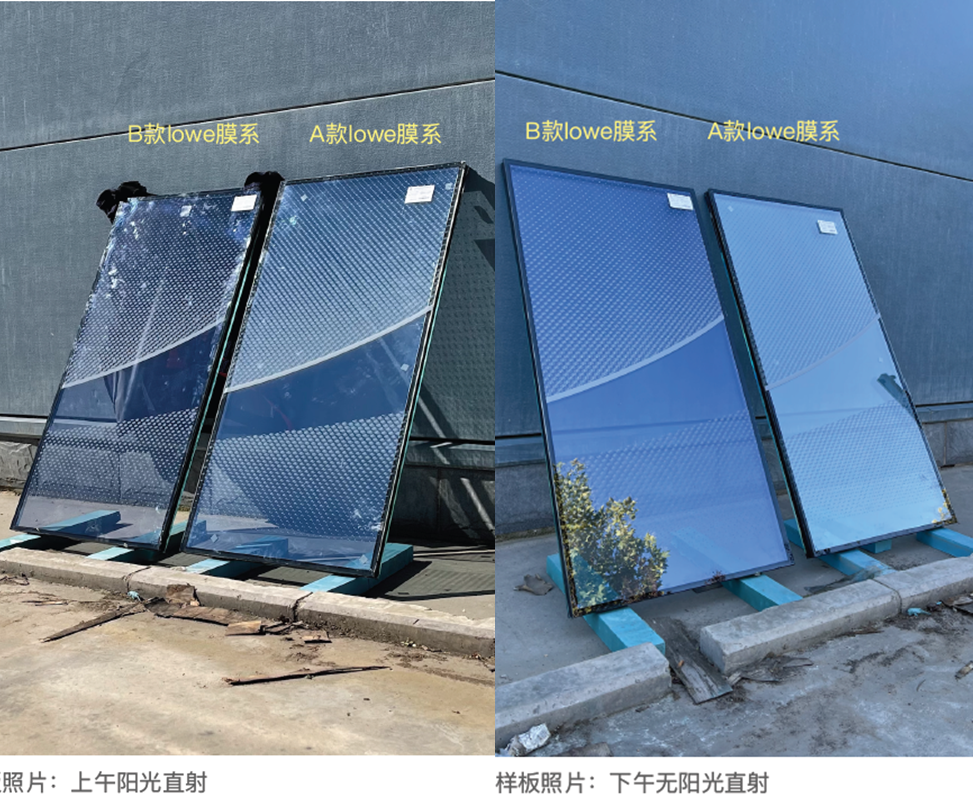

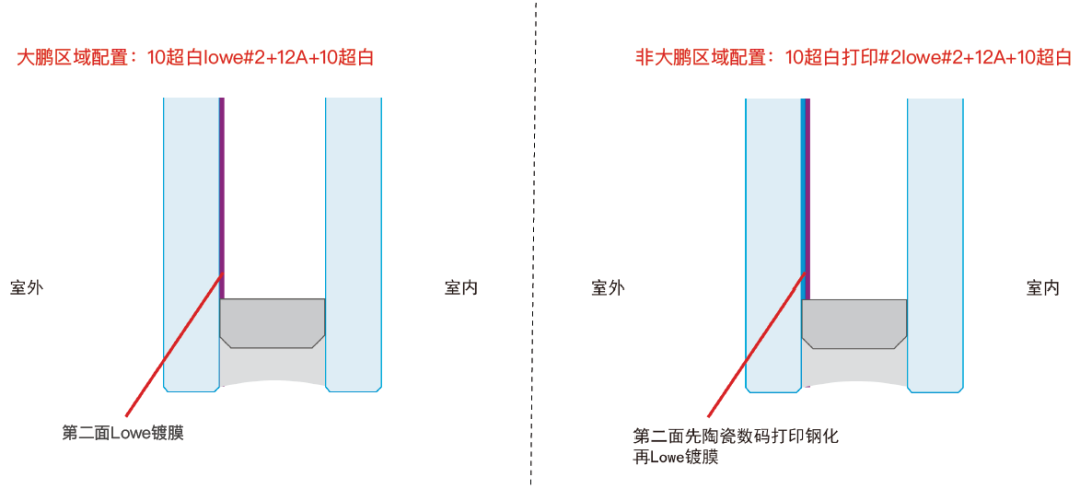

In order to achieve the effect of refreshing and transparent facade, the glass curtain wall of the main facade of the R&D building adopts digital printing technology, showing the effect of a great hawk spreads its wings.

The glass curtain wall adopts 10(Low-E)+12A+10 hollow ultra-white tempered glass, and the non-pattern position uses deep and light digital printing to form a natural and flexible pattern effect.

▲ realistic picture

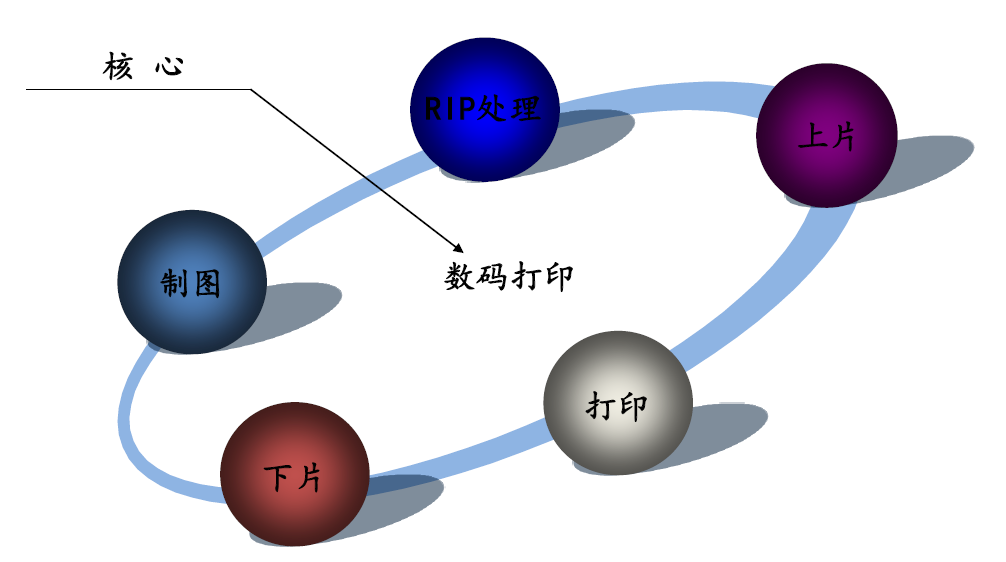

Digital printing glass is a new type of glass material with durable wear resistance, UV radiation resistance and high weather resistance, which is obtained by identifying and processing pictures through the system of digital printer, printing ceramic ink on the surface of glass according to the pattern, drying and tempering, and permanently sintering ceramic ink on the surface of glass. The color of digital printing glass is rich and colorful, not limited to single color or double color.

The glass produced by digital printing is superior to traditional screen and drum printing in terms of ink surface quality, ink layer uniformity, smoothness, color richness and diversity, and process flow.

It has four basic elements : PDF files and pictures, ceramic ink, glass digital printer. The ink is composed of peng zinc silicate powder, no toxic heavy metals, with inorganic pigments in the mixture of solvent and organic polymer to color, ink color mainly has six kinds : white (W), black (K), blue (C), red (M), yellow (Y), green (G), most of the color can be mixed by the six kinds of ink.

▲ Digital printing production factors

▲ processing line

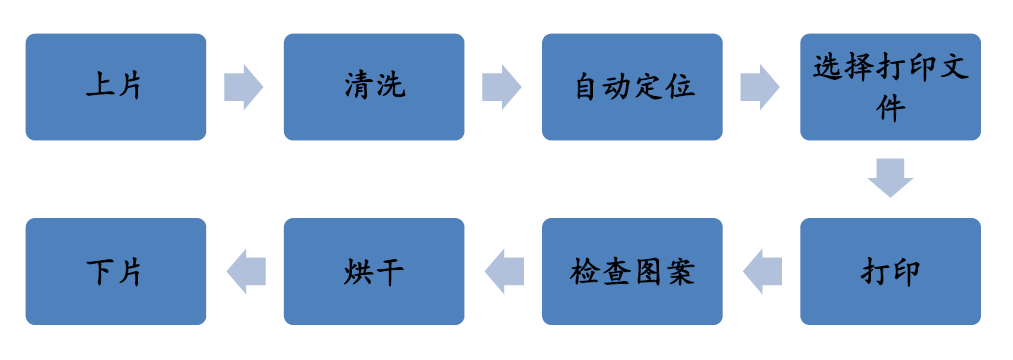

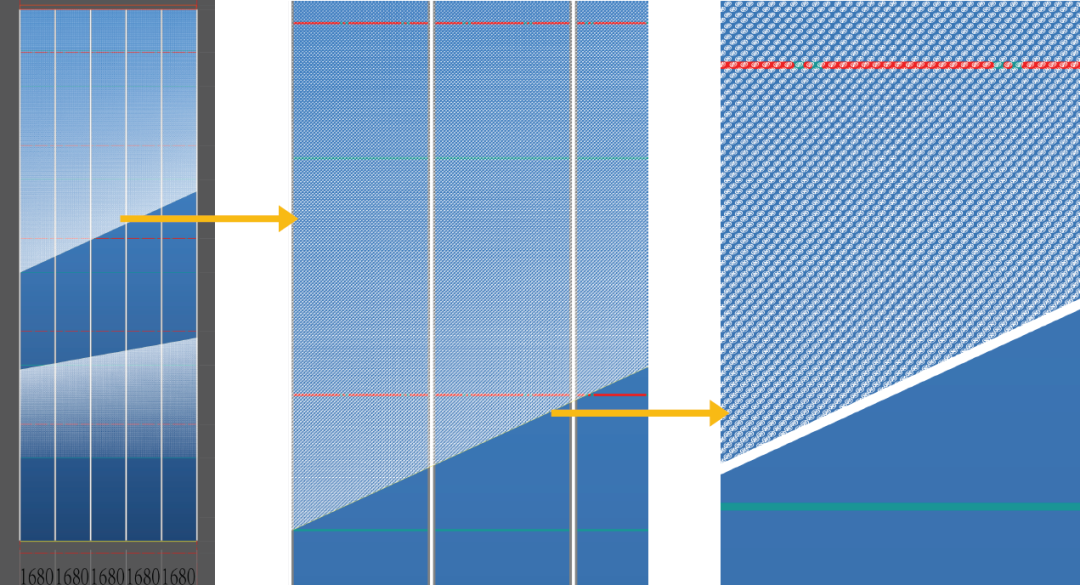

Digital printing glass curtain wall as a highlight of the project, from the program stage, the designer and the manufacturer 's technical personnel to work together, from the printing area selection, processing difficulty, effect presentation and other aspects of the comparison, excellence, and ultimately selected in the non-Dapeng display area for digital printing.

▲ print area selection

▲ Comparison of printing effect at Dapeng

▲ Comparison of printing effects at non-dapeng

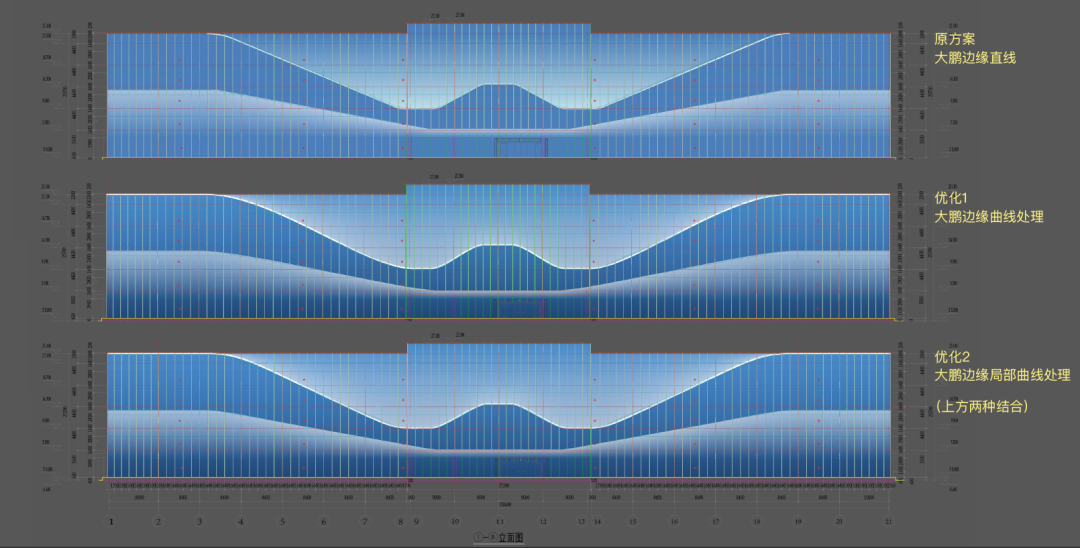

The contour effect of Dapeng pattern is optimized, and some positions are turned from straight to curved to enhance its flexible and elegant feeling.

▲ Scheme optimization process version

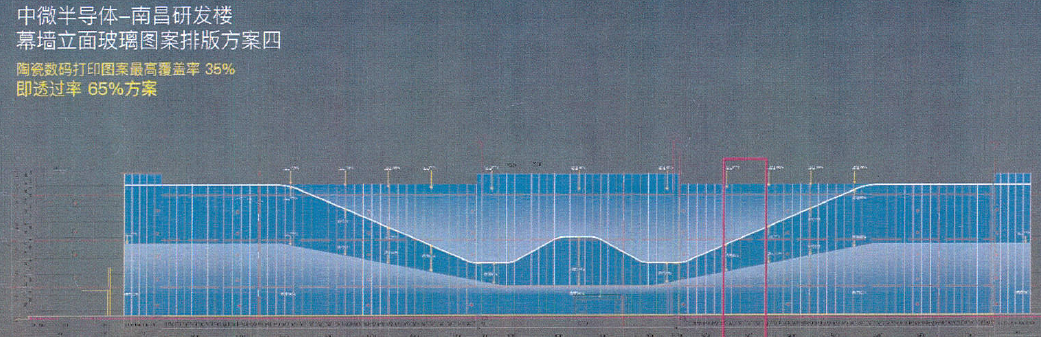

▲ Final version of scheme optimization

▲ optimized pattern

Digital printing technology has no requirement for printed patterns. When the pattern coverage is less than 50% or equal to 100%, the glazed surface can be located in the middle of the glue.

▲ hyaline cap texture

More live photos of the scene:

This project includes a research and development building and three industrial plants, including a large number of metal curtain wall sandwich panels (sandwich panels). The east, west and north facades of the research and development building and the walls of 1#, 2# and 3# plants all use this material.

▲ effect picture

The metal curtain wall sandwich panel system has excellent thermal insulation, aesthetics, fire prevention, energy saving and other properties, and the facade image is full of modern science and technology, which is in line with the high-end technology image of AMEC.

At the beginning of the scheme selection, it is worried that the surface material will be rusted, faded, and dirty on the surface after long-term wind, sun, rain and rain. The design team conducted research and comparison on various surface manufacturers for this situation, and on-the-spot investigation. Finally, the cost-effective aluminum-coated zinc-magnesium color steel plate was selected, and the paint used SRP coating and inorganic ceramic pigment, and had self-cleaning function. The coating system using mica pigment presents different color luster at different angles. While giving the steel plate a permanent and beautiful appearance, it has excellent corrosion resistance and long service life.

▲ realistic picture

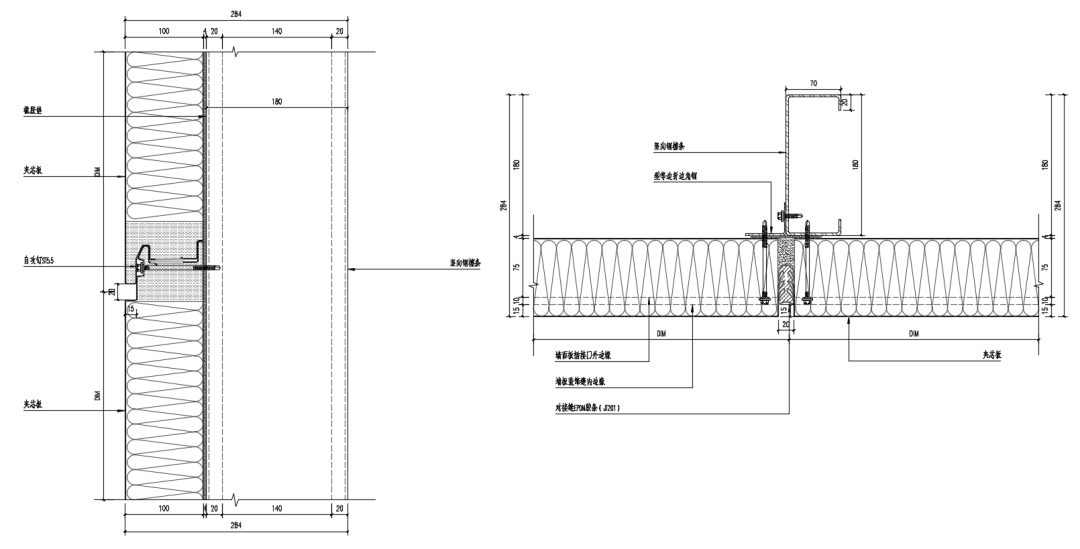

The flatness of the metal plate affects the effect of the entire building fa ade, so the practice of the sandwich plate, the split, and the closing treatment of each handover position are very important.

▲ standard node

The joint of the plate needs to adopt a high weather-resistant EPDM flexible waterproof and cold-proof bridge rubber pad with a water guide tank. The left and right sides of the rubber pad are serrated, and the middle part is engaged with the joint of the plate. The buckle position between the plates needs to be pre-injected with butyl rubber to ensure the air tightness and water tightness between the plates.

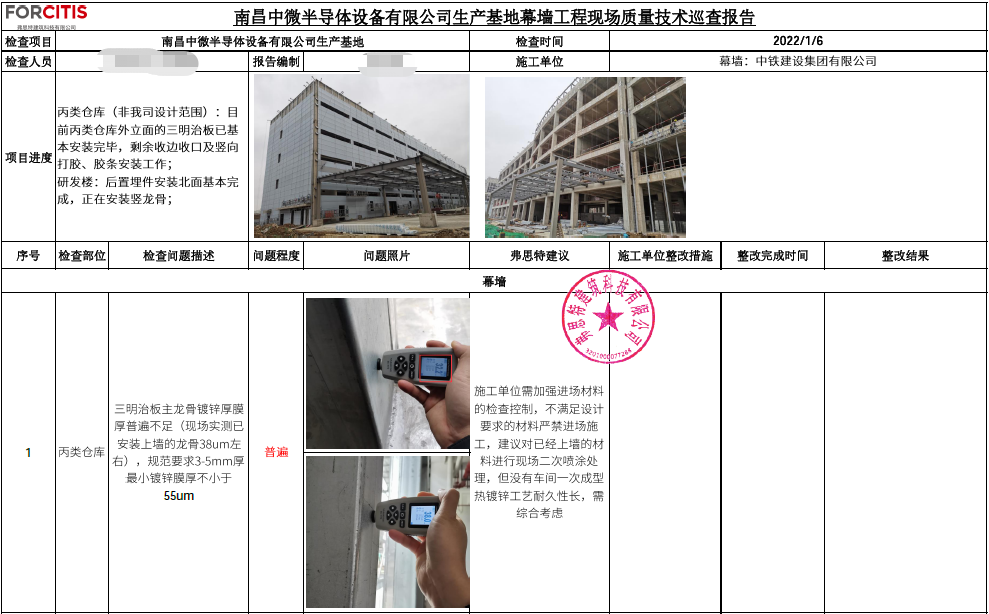

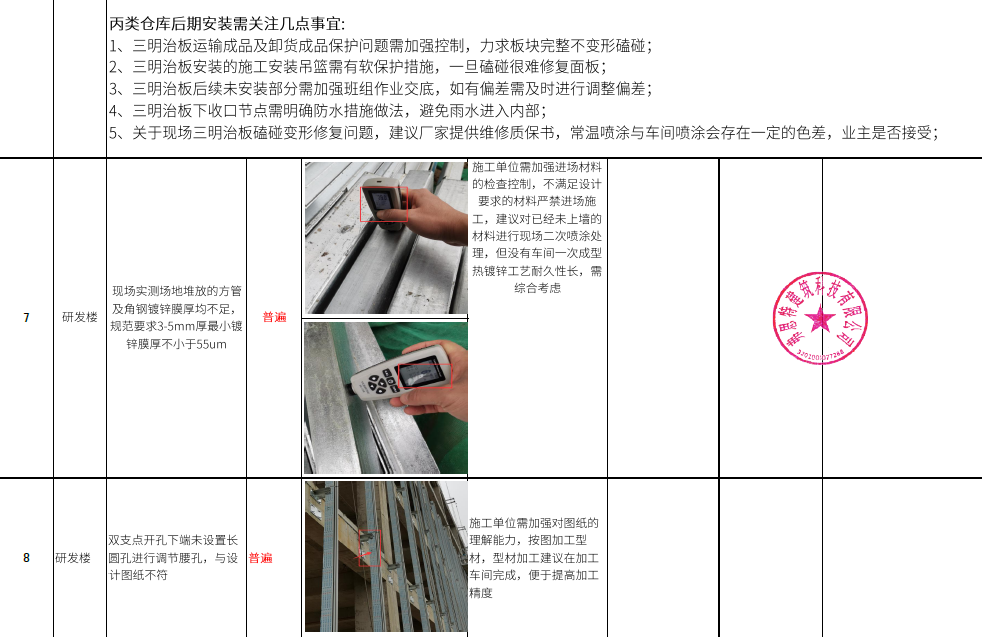

At the same time, Forcitis provides on-site inspection services for this project. Professional management engineers and consultant engineers inspect together, find problems, give professional rectification opinions according to corresponding norms and regulations, and make corresponding risk tips.

▲ some inspection reports

Pictures of the on-site inspection:

The completion of AMEC Nanchang R&D base project provides a strong guarantee for the company to continuously improve its R&D and production capacity, and also lays a solid foundation for sustained high-speed, stable, healthy and safe development.